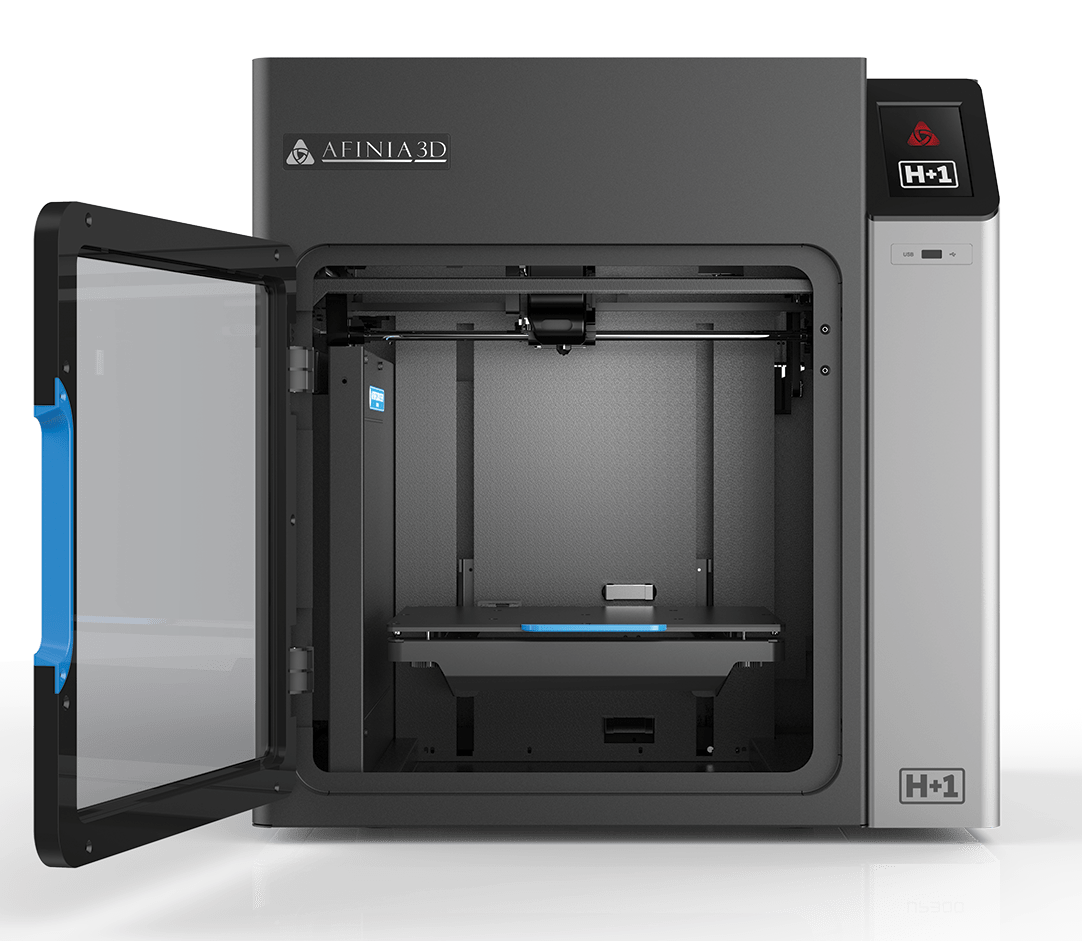

Afinia H+1 3D Printer

Versatility meets precision performance

The Afinia H+1 3D printer combines a large build volume with consistency of performance. Material-specific printheads are included, ensuring optimal print quality and compatibility across a wide range of filament types.

- – Material-specific printhead system for optimal quality and compatibility

- – Circulating dual-filtered system

- – Automated leveling and height sensing

- – 2-sided interchangeable build plates

- – Power loss print recovery filament run-out detection

- – Customizable temperature controls & filament profiles

- – Print queue for auto job management

- – Large build volume (10x8x8.8 inches)

- – Enclosed, heated platform & chamber

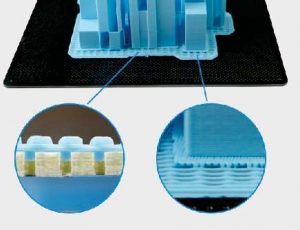

- – Smart support material technology

- – Multiple connectivity options (WiFi, USB, LAN, & USB Flash Drive)

New to the H+1

Out-of-the-Box 3D Printing

The Afinia H-Series 3D Printers provide a true “Out-of-the-Box 3D Printing Experience” as the 3D Printers comes fully assembled with easy-to-install software for both the PC and Mac.

Improved Material Compatibility

The Afinia H+1 comes with three material-specific printheads: ABS, PLA, and TPU. In contrast to the one-size-fits-all extruder, these interchangeable heads are designed specifically for each material’s characteristics, allowing for greater filament control and a better finish.

Full metal printhead tailored to high-temperature material

Full metal printhead tailored to high-temperature material

- – ABS, ABS+

- – ASA

- – PETG

- – Polycarbonate

- – Polypropylene

- – Nylon

- – Carbon Fiber filled depending on base material

Effective cooling system and PTFE feed path tailored to low temperature material

Effective cooling system and PTFE feed path tailored to low temperature material

- – PLA

- – Metal Filled PLA

- – Wood Filled PLA

- – Carbon Fiber Filled depending on the base material

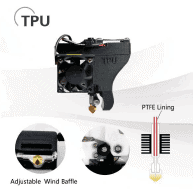

Spring-loaded feed path, double gear, PTFE feed path, and larger nozzle size tailored to flexible material

Spring-loaded feed path, double gear, PTFE feed path, and larger nozzle size tailored to flexible material

- – TPU and flexible filament

AIDEX. THE BEST PEOPLE + THE BEST PRODUCTS.

Providing insight, selection, installation, and ongoing support of the latest educational and career technology.

For more information or to contact Aidex, your Afinia 3D Authorized Reseller, call 800-251-9935 or email Info@Aidex.com